It is the most widely used printing technique on the market, suitable for printing on paper, cardboard, plastic and other flat materials. Offset is used for printing books, newspaper, stationery, packaging, etc. The following video (provided by Lorenzo) explains the offset process in more depth which I have summarised below:

In addition to size, page count, colour coverage and quantity the estimator also evaluates press time, special paper order, labour and shipping costs. This must be done efficiently to get the best price. Each file is inspected carefully to make sure they have all the fonts, colour palettes and high resolution graphics - a sample is then given to the client

The colours are then separated into the four colour process colours or PMS (Pantone) colours. Each colour is then etched into thin, aluminium plates which are then taken to the press to print the job.

The press is comprised of four separate presses, one in each tower. The four plates are then wrapped around a plate cylinder in each of these 'towers'.

There needs to be the right balance of ink and water to keep the non image area, clean. The image is transferred as a reverse image from the plate to a blanket (rubber pad) which is locked tightly around the blanket cylinder. The paper is moved from unit to unit to create the full composite image. The impression cylinder squeezes the paper at just the right pressure to make sure the print is as smooth as possible.

Flexography

In flexography a flexible (typically rubber) printing plate is used, which extends the range of substrates that can be printed on. A positive, mirror image rubber polymer plate on a cylinder, transfers 'sticky ink' directly onto the print surface. It can be used for printing on almost any type of substrate including plastic, cellophane and paper. Examples of products are crisp packets and bottle labels.

- Ink Roller The Ink Roller transfers the ink that is located in the ink pan to the second roller, which is the Anilox Roller.

- Anilox Roller This is what makes Flexography unique. The Anilox Roller meters the predetermined ink that is transferred for uniform thickness. It has engraved cells that carry a certain capacity of inks that can only be seen with a microscope.

- Plate Cylinder The Plate Cylinder holds the printing plate, which is soft flexible rubber. Sticky 2-way tape is used to mount the plate to the Plate Cylinder.

- Impression Cylinder The Impression Cylinder applies pressure to the Plate Cylinder, where the image is transferred to the substrate.

Benefits of Flexography printing

- Better resolution and ability to print four color process (or more).

- Increased ability to reproduce highlight tonal values.

- Uses a wider range of inks, and can print on a variety of different materials.

- Inks have low viscosity to enable faster drying

- Faster production and lower costs.

Digital print

(definition courtesy of wikipedia) Digital printing refers to methods of printing from a digital based image directly to a variety of media. It usually refers to professional printing where small run jobs from desktop publishing and other digital sources are printed using large format and/or high volume laser or inkjet printers.

Digital printing has a higher cost per page than more traditional offset printing methods but this price is usually offset by the cost saving in avoiding all the technical steps in between needed to make printing plates. It also allows for on demand printing, short turn around, and even a modification of the image (variable data) with each impression. The savings in labor and ever increasing capability of digital presses means digital printing is reaching a point where it will match or supersede offset printing technology's ability to produce larger print runs at a low price

Rotogravure

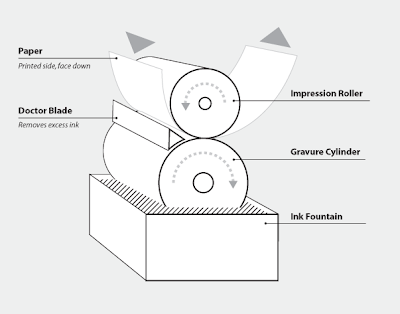

Gravure is a type of the intaglio printing process that involves engraving the image onto an image carrier. Gravure printing presses two large print reels of paper together rather than sheets of paper. This type of printing is the fastest and widest printing press in operation. It is capable of transferring more ink to the paper than other printing processes, and is also noted for its remarkable density range.

A gravure printing press has one designated printing unit for each color, commonly CMYK. While the press is in operation, the engraved cylinder is partially immersed into the ink fountain, filling the recessed cells. As the cylinder rotates, it draws ink out of the fountain with it. Acting as a squeegee, the doctor blade scrapes the cylinder before it makes contact with the paper removing ink from the non-printing (non-recessed) areas. Next, the paper gets sandwiched between the impression roller and the gravure cylinder. This is where the ink gets transferred from the recessed cells to the paper.

The purpose of the impression roller is to apply force, by pressing the paper onto the gravure cylinder, ensuring maximum coverage of ink. Then the paper goes through a dryer because it must be completely dry before going through the next color unit and absorbing another coat of ink.

Screen print

Screen printing is a printing technique that uses a woven mesh to support an ink-blocking stencil. The attached stencil forms open areas of mesh that transfer ink or other printable materials which can be pressed through the mesh as a sharp-edged image onto a substrate. A roller or squeegee is moved across the screen stencil, forcing or pumping ink past the threads of the woven mesh in the open areas.

Screen printing is also a stencil method of print making in which a design is imposed on a screen of silk or other fine mesh, with blank areas coated with an impermeable substance, and ink is forced through the mesh onto the printing surface. It is also known as silkscreen, serigraphy, and serigraph printing.

Screenprinting is more versatile than traditional printing techniques. The surface does not have to be printed under pressure, unlike etching or lithography, and it does not have to be planar. Different inks can be used to work with a variety of materials, such as textiles, ceramics, wood, paper, glass, metal, and plastic. As a result, screenprinting is used in many different industries, including:

- Balloons

- Clothing

- Decals

- Medical devices

- Printed electronics, including circuit board printing

- Product labels

- Signs and displays

- Snowboard graphics

- Textile fabric

- Thick film technology

- ... and so on

CMYK printing (screen angles)

To improve print quality and reduce moiré patterns, the screen for each color is set at a different angle. While the angles depend on how many colors are used and the preference of the press operator, typical CMYK process printing uses any of the following screen angles (in degrees)

C: 15, 15, 105

M: 74, 45, 75

Y: 0, 0, 90

K: 45, 75, 15

No comments:

Post a Comment